Arizona Finishing Wet Painting Services

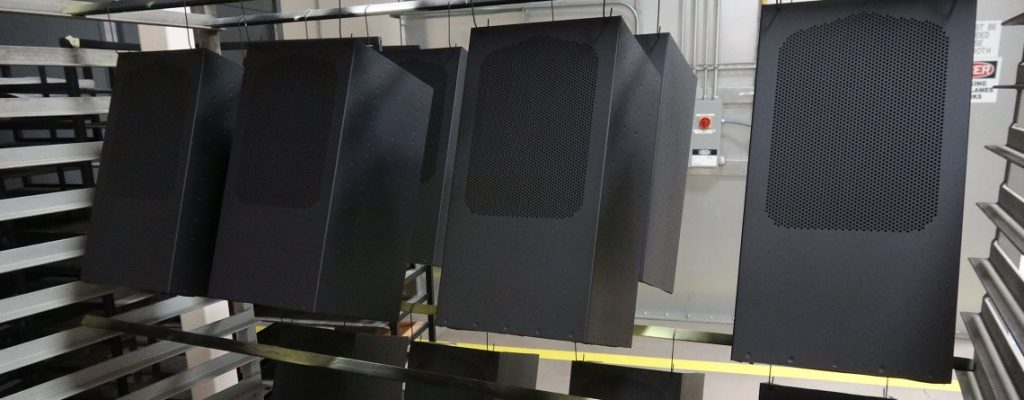

- 760 ft. automated conveyor paint line can run anywhere from 4-12 ft./min. depending on the part

- Two (2) quad paint application liquid/powder booths separated by an infrared gas catalytic 4 minute cure system

- Four (4) large batch booths with their own dedicated oven

- ESD assembly, metal silk screening, and pick-up/delivery available

- AS9100 and Mil-Spec certified

This custom paint facility is ready to meet the needs of our currently growing customer base, come and be a part of the future with us!

Arizona Finishing: We’re here to help

The vast number of coating options and applications can be staggering.

If you have questions about which type of coating is correct for your particular product, contact the metal finishing experts at Arizona Finishing today!

Our experienced team is standing by ready to help you make an informed decision about what type of coating to use for your product.

Why Choose Liquid Based Paint Coatings?

While it’s true that powder coating is cheaper and more efficient than using a liquid-based spray paint, powder coating is not applicable in every case.

There are a number of reasons one would choose a liquid based paint rather than powder coating:

No Rubber or PlasticClass A FinishSize RestrictionsThin CoatingsTouch-Up

If a part contains any rubber or plastic then it would not be suitable for powder coating because the rubber would melt during the baking process. Liquid-based paint, in this case, would be a good alternative.

Although the gap has largely been narrowed in the last few years, liquid paint is thought to deliver higher quality ‘Class A’ finishes. This is why automakers by and large still use a liquid-based spray when manufacturing automobiles, although with the advancement of powder coating finishes, this is slowly beginning to change. For Class A finishes, a solvent-based liquid paint would be the preferred coating choice.

Another factor to consider is size. If a part is too large and exceeds the dimensions of the curing oven, then a liquid-based coating would be the obvious solution. This is because liquid based paint doesn’t need a specific temperature to dry (although the drying process can be sped up by applying mild heat.)

Thin coatings (less than 6 millimeters) are difficult to achieve with powder coating. This is due to the mechanics behind powder coating; you have less control over the amount and speed at which the powder is applied to your workpiece. If a particularly thin coating is required, then a liquid based paint would be the superior choice.

Liquid-based coated piece can be ‘touched-up’ or a portion can be sanded and refinished with little noticeable effect on the finished part. Powder coatings cannot be ‘touched-up’ – generally, the previous coating will need to be completely removed, the part cleaned and then powder coated again.

Arizona Finishing also offers Electrostatic Coating (or e-coating) which uses electricity to efficiently apply either paint or powder to a workpiece.