The benefits of powder coating vs. liquid paint are astounding.

Powder coating beats out liquid paint coatings and uncoated parts by a wide margin.

Let’s examine four reasons you should consider powder coating when selecting a finish for your metal parts.

Powder Coating is Eco Friendly

Powder coats contain no solvents or volatile organic compounds (VACs). These compounds are found in most industrial liquid paints, and are extremely harmful for people and the environment.

Unused powder can easily be collected, recycled and reused.

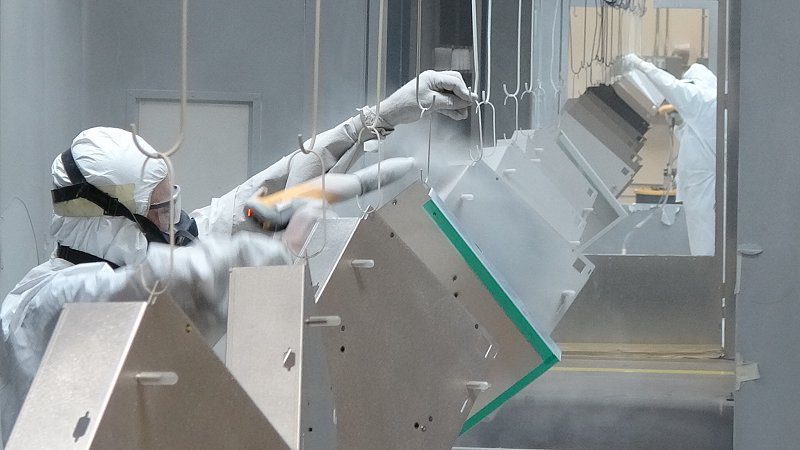

Clean, Smooth and Consistent

Powder coating produces a smooth, consistent layer on any product. Your powder coat can be as thick as you like, since it won’t create any drips, sags, or uneven coverage. Powder is available in a wide range of colors, textures, and visual effects (glitter, metallic, fluorescent, stc.)

Powder Coating Resists Corrosion

Powder coating is incredibly durable, providing a protective finish for metals for longer periods of time. It’s more resistant to chipping, scratching and fading, and doesn’t need touch ups as often as liquid paints.

Compared to paint, powder coating is 60% more resistant to solvents, 74% more resistant to salt spray, and 94% more resistant to impact. (Steel King)

Powder Coating is Cost-Effective

It’s durable, reusable, produces little waste, doesn’t need touch-ups, looks great for longer periods of time and is safe for humans and the environment. All of these factors reduce the overall coating costs, whether directly (recycling powder for multiple uses) or indirectly )avoiding taxes and fines for pollution.)

Overall, powder coating is simply the best option when it comes to selecting a metal coating for your part.