Powder Coating in Phoenix, AZ: Setting a New Standard

In Phoenix, there’s no shortage of powder coating companies to choose from, but finding the perfect balance between speed and quality can be a challenge. Some providers prioritize fast turnarounds at the expense of quality, while others focus on precision, sacrificing efficiency.

That’s where Arizona Finishing stands apart.

Introducing Arizona Finishing: The Valley’s Premier Industrial Coating Provider

As the Valley’s premier industrial coating provider, we specialize in powder coating, liquid paint, and electrostatic coatings, offering cutting-edge finishes with the fastest lead times and competitive pricing.

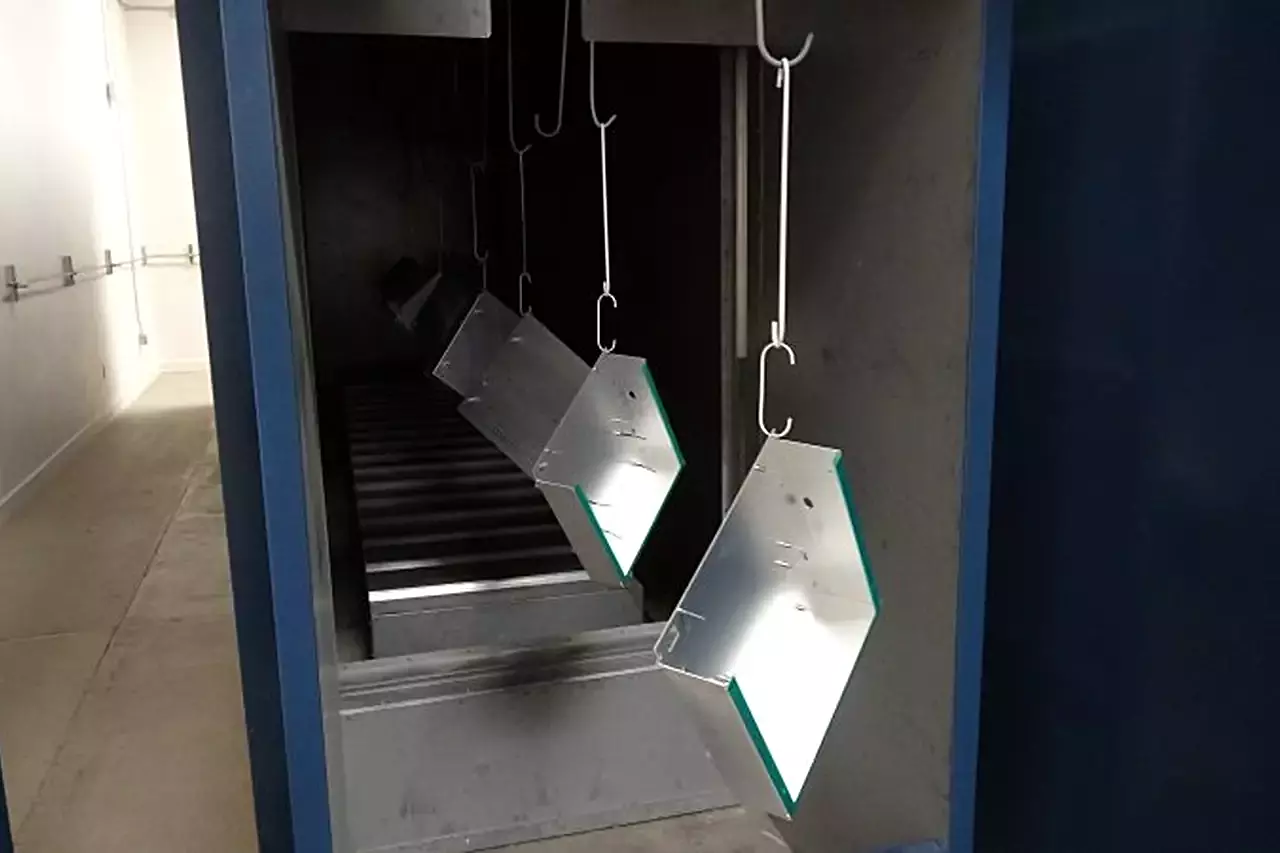

State-of-the-Art Facility and Equipment

Our new state-of-the-art facility is equipped with a 760-ft variable-speed conveyor line and dual quad paint booths, all enhanced by an infrared gas catalytic cure system. We also have four large batch booths, each with its own dedicated oven, allowing us to accommodate projects of any size.

Value-Added Services

Arizona Finishing offers a range of value-added services to streamline your production process, including:

- ESD product assembly

- Product testing (gloss meter, spectrophotometer, thickness meter)

- ISO 7 (Class 10,000) clean room assembly in our 890 sq. ft. facility

- Metal screen printing for logos, product details, or custom designs

- Custom packaging, shipping, and delivery to your specifications

Commitment to Quality, Speed, and Efficiency

Our commitment to quality, speed, and efficiency is backed by industry-leading certifications: we are ISO 9001 compliant as well as ITAR and MIL-SPEC approved, ensuring the highest standards from start to finish.

Experience You Can Trust

With nearly 20 years of experience, Arizona Finishing delivers on-time, every time. Call us today for a free estimate and see how we can enhance your supply chain!