- 760 ft. automated conveyor paint line can run anywhere from 4-12 ft./min. depending on the part

- Two (2) quad paint application liquid/powder booths separated by an infrared gas catalytic 4 minute cure system

- Four (4) large batch booths with their own dedicated oven

- ESD assembly, metal silk screening, and pick-up/delivery available

- AS9100 and Mil-Spec certified

This custom paint facility is ready to meet the needs of our currently growing customer base, come and be a part of the future with us!

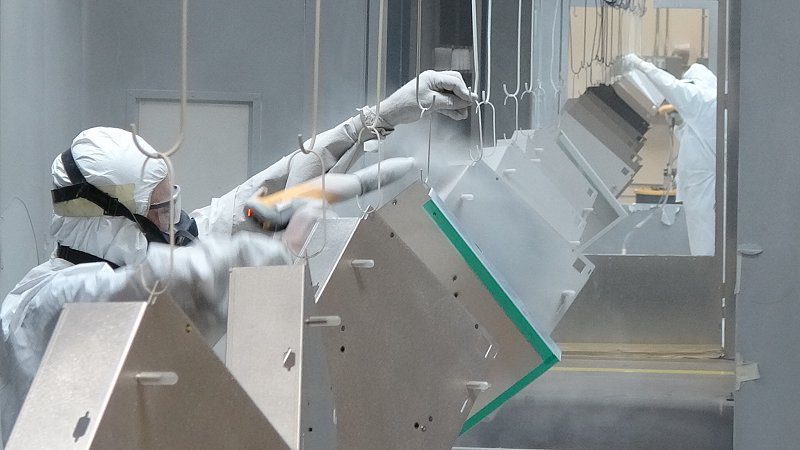

Electrostatic coating is a coating process that uses charged particles to more efficiently paint a metal part.

Either powder or liquid paint may be used in the process.

The electrostatic painting process uses the “magnetic effect” of electrical current to draw the electrostatic paint onto the metal surface being painted. The “wrap-around effect” of electrostatic painting means magnetic draws the paint onto the surface

- Uses a high voltage electrostatic charge which is applied to both the workpiece and the sprayer mechanism

- Uses 95% of sprayed paint due to reduced overspray and better wrap-around

- Paint materials can be either powdered or liquid

- Workpieces must be conductive

- Workpieces are usually baked after coated

- The baked on paint adheres extremely well and is difficult to remove without aggressive means of removal.

Powder coating… wet paint… electrostatic painting… there are so many coating options!

What is the best method to coat for your product?

At Arizona Finishing that’s what we do, it’s all we do.

We’ve been a quality B2B (business-to-business) manufacturer in the Valley of the Sun for over 20 years.